© Spokane Industries, All Rights Reserved

Menu

High Performance

Mining Wear Parts

High Performance Mining Wear Parts

Spokane provides high quality, high performance castings for the mining industry. With parts in both abrasion resistant steel and iron and our patented Si-Tec® Ultra Wear Resistant Ceramic Composites, we have something for every application. And with our Si-Tec® castings lasting 1.5 to 4 times the life of standard parts, you can reduce your operating costs, decrease change out times, and increase safety.

Increased Wear Life

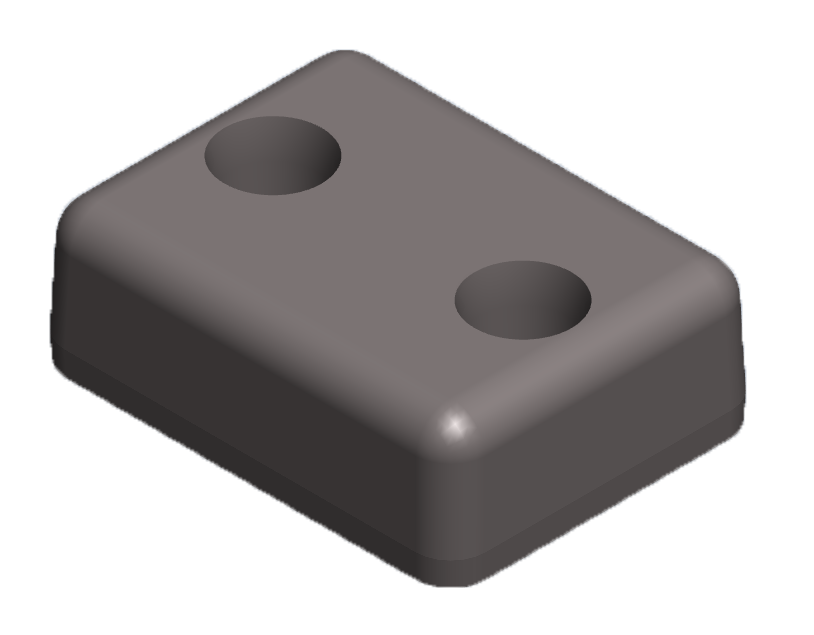

Industrial mining chutes are subjected to a great amount of wear. Spokane Industries provides abrasion resistant steel and high chromium white iron along with our patented Si-Tec® Ceramic composite chute liners and plates to safeguard them from the wear and tear of day to day operations.

Chute liners are a cost-effective means of achieving protection and extending the life of all your chutes, and our Si-Tec® liners can double the life of standard chrome liners in many applications.

We offer a broad range of materials and designs specifically for mining applications where there is high sliding abrasion. Spokane Si‑Tec® Ceramic Composite materials address particularly challenging wear areas in chutes and conveyor systems, and can often double the life compared to high chrome iron and many multiples of plate steel.

Increased Wear Life

Industrial mining chutes take a great amount of impact. Spokane Industries provides steel and our patented Si-Tec® Ceramic composite chute liners and plates to safeguard them from the wear and tear of day to day operations.

Chute liners are a cost-effective means of achieving protection and extending the life of all your chutes, and our Si-Tec® liners can double the life of standard chrome liners in many applications.

We develop unique materials and an unparalleled line of wear resistant products specifically for mining applications where there is high sliding abrasion. Spokane Si‑Tec® Ceramic Composite materials address particularly challenging wear areas in chutes and conveyor systems. With Si‑Tec® liners, wear life is typically twice, or more than that of high chrome iron and many multiples of plate steel.

Designed and Produced in the USA

All Spokane Industries Mining Wear Parts are designed and made in the USA. Our standard wear parts include competitive lead times and help you get the parts you need, when you need them.

In addition to our standard chute liners, our engineering team can design custom solutions specifically to address your critical high-abrasion wear areas. Contact us to see how our we can help you increase productivity and uptime.

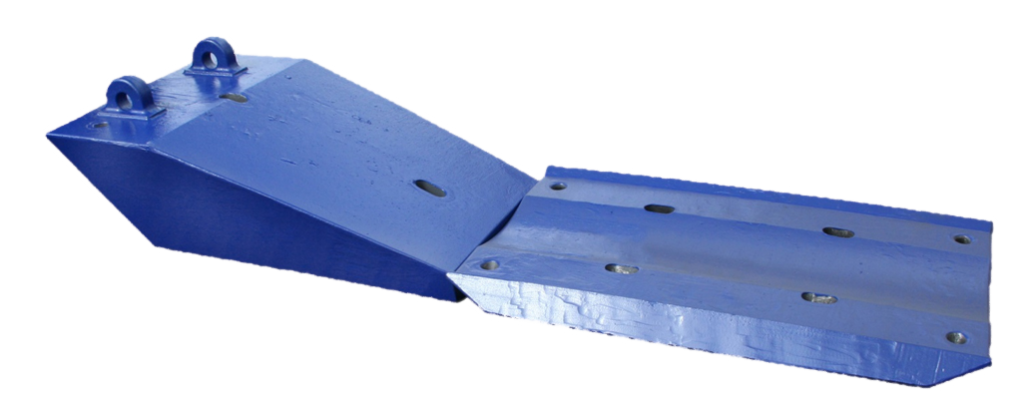

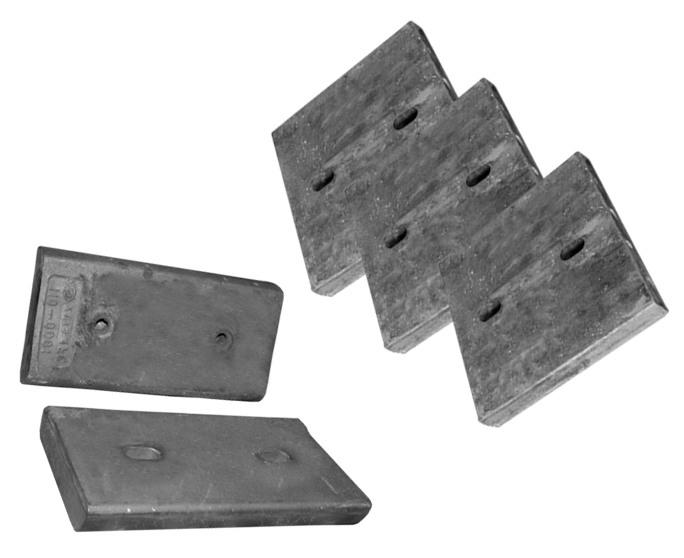

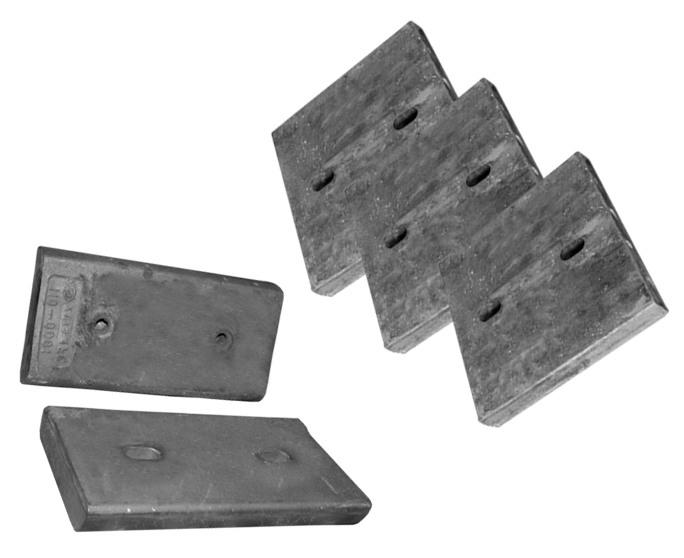

Bolt on Wear Runners Available Now!

Spokane now makes bolt on wear runners! Use them to extended wear life on dragline buckets, excavator buckets, and any other areas that need additional life.

In addition, you can get bolt on wear runners with our patented Si-Tec® ceramic embedded technology. These parts have improved wear life by 65%! Come and see the Si-Tec® Advantage!

Bolt on Wear Runners Available Now!

Spokane now makes bolt on wear runners! Use them to extended wear life on dragline buckets, excavator buckets, and any other areas that need additional life.

In addition, you can get bolt on wear runners with our patented Si-Tec® ceramic embedded technology. These parts have improved wear life by 65%! Come and see the Si-Tec® Advantage!

High Chrome White Iron

Elevate the durability and efficiency of your industrial equipment by choosing high chrome white iron parts from Spokane Industries. Engineered for optimal wear resistance, these parts excel in demanding mining applications.

The high chrome white iron composition ensures superior hardness and toughness, minimizing downtime and maintenance costs while extending the operational life of equipment. Beyond their robust performance, Spokane Industries’ commitment to quality ensures that these high chrome white iron parts seamlessly integrate into your specific application requirements.

Invest in lasting value with Spokane Industries’ high chrome white iron parts – a reliable solution that withstands abrasive environments and contributes to the overall efficiency of your operations.